NEW!

CLEAN ROOM

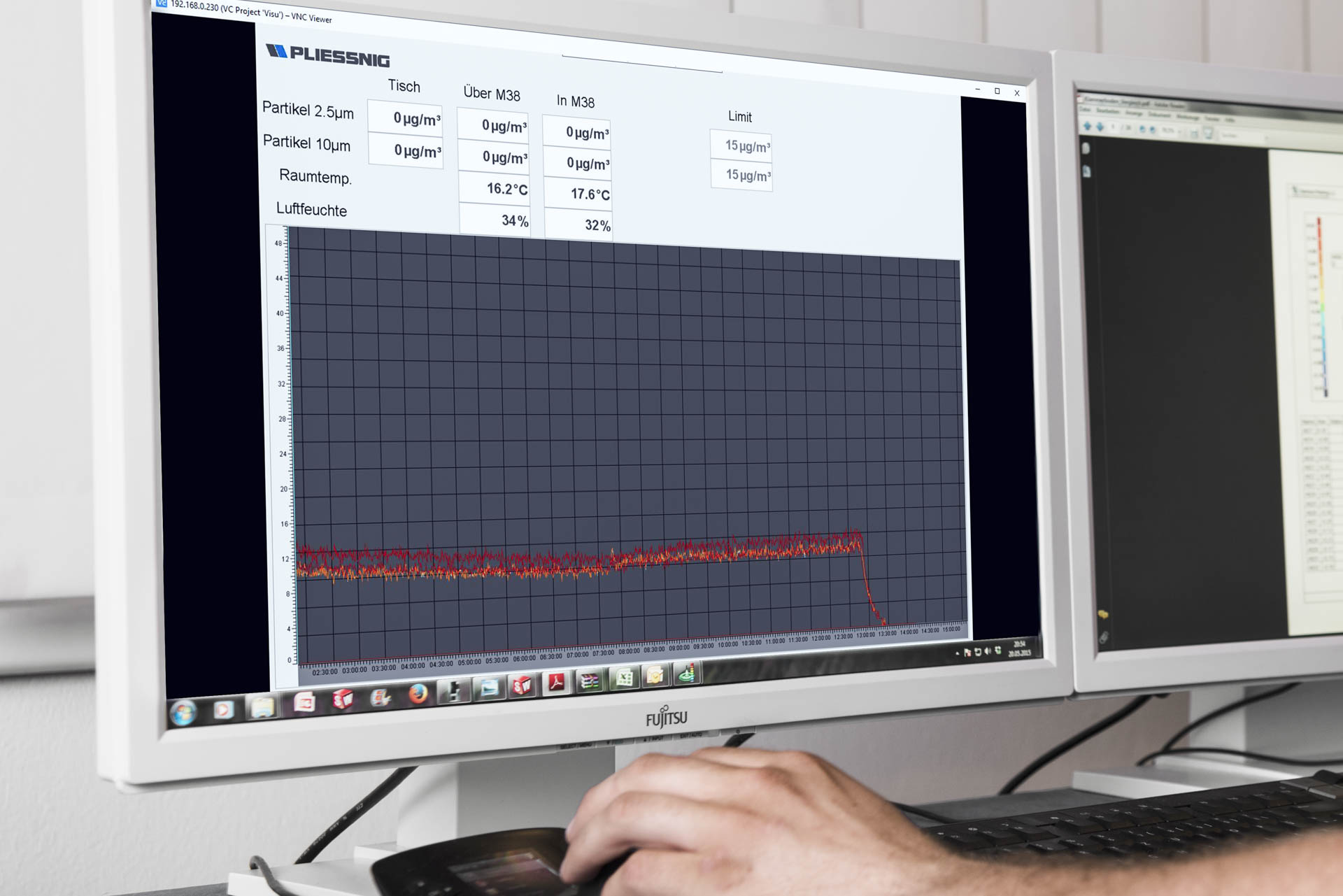

PUREST QUALITY

Since 2022 we have a new self-contained hall (clean room) for the production of sensitive products for industries where the purest quality is required, such as:

– medical technology

– pharmaceutics

– optical lenses

A ventilation system equipped with particle filters generates a constant temperature and overpressure, which, together with the existing airlocks, ensures that external contamination is virtually eliminated. The parameters are monitored fully automatically. In the event of deviations, intervention in the system-certified production process is possible immediately.

All products and components leave the clean room hermetically sealed, so that contamination can be ruled out even after the production process.

COMBIMELT

TECHNOLOGY

Combimelt technology enables two or more materials to be joined in one manufacturing step and in one production cell. The result is multifunctional plastic components. Special design requirements, such as color effects, can thus be specifically combined with different material properties. Examples: Orthopedic insoles, reproducible marble structures.

COINJECTION AND

ROTATING TABLE TECHNOLOGY

The modern injection molding process opens up new design and savings potential. Our machinery enables us to produce multi-component parts in the weight classes from 0.1 to 2600 grams flexibly, cost-efficiently and in the highest quality.

Several 6-axis robots take care of the placement. Thus, by inserting textiles into 2-component molds, 3-component parts can be manufactured. Examples: Mechanical engineering, technical precision injection molded parts, complete solutions with metal part connections.

MASHINE

PARK

– 40 injection molding machines with 10 – 1,100 t clamping force

– 7 two-component plants with rotary table from ø 520 – 1,200 mm