DEVELOPMENT &

INNOVATION

From the constructive development work to series production, we take care of the long way from the idea, planning, tool design, construction of prototypes to series production.

– prototyping – fill-analysis -product & process development

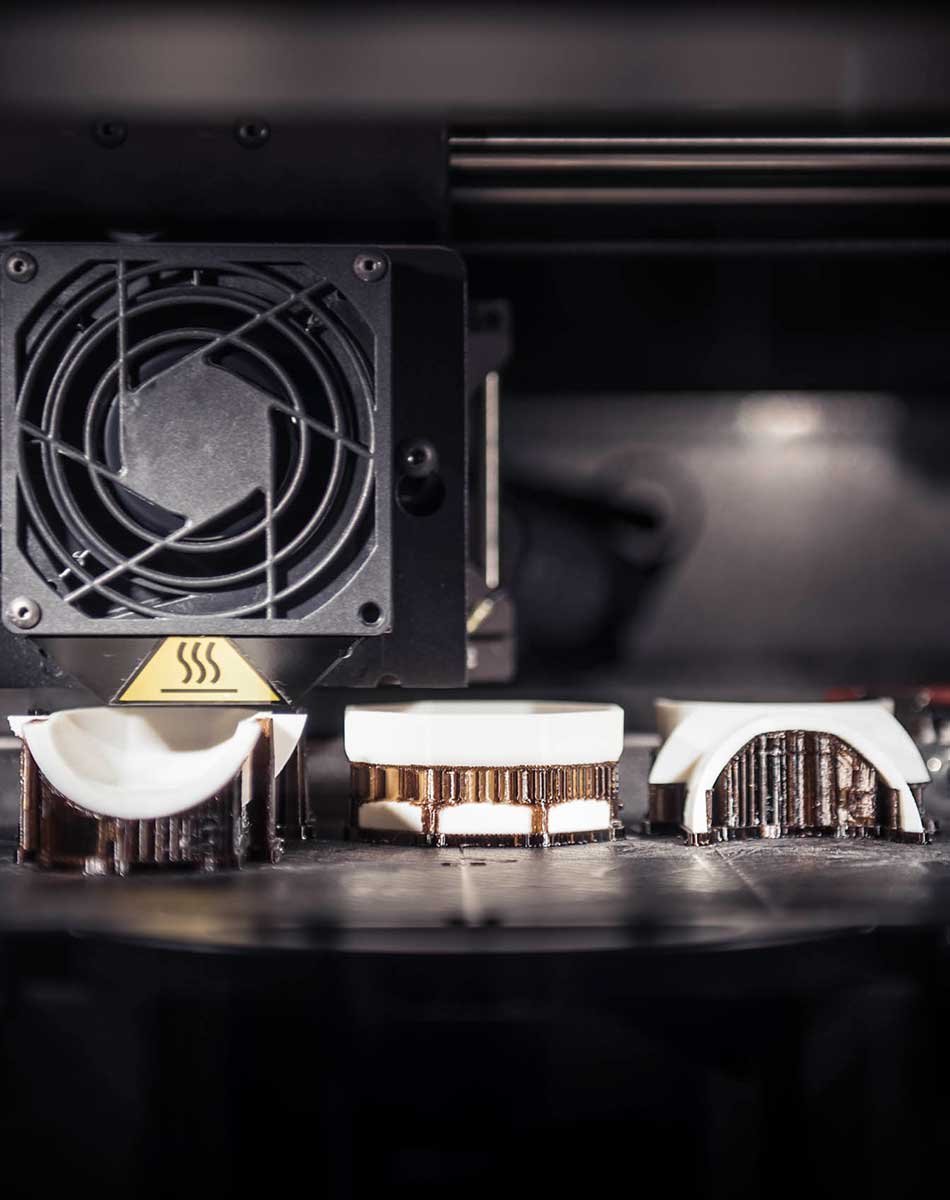

PROTOTYPING

Nothing explains a new idea as well and accurately as a three–dimensional model. The model allows to check form, fit and function. In addition, development cycles are accelerated and thus development and construction times are reduced.

TECHNICAL DETAILS:

• Building Space Size (Maximum Volume of the Workpiece): 203 mm x 203 mm x 305 mm

• Material: Common Thermoplastic ABS (Acrylonitrile Butadiene Styrene)

• Layer Thickness (Resolution): 0.254 mm or 0.178 mm

In addition to drilling, milling, thread cutting, ABS models can be painted or chrome plated.

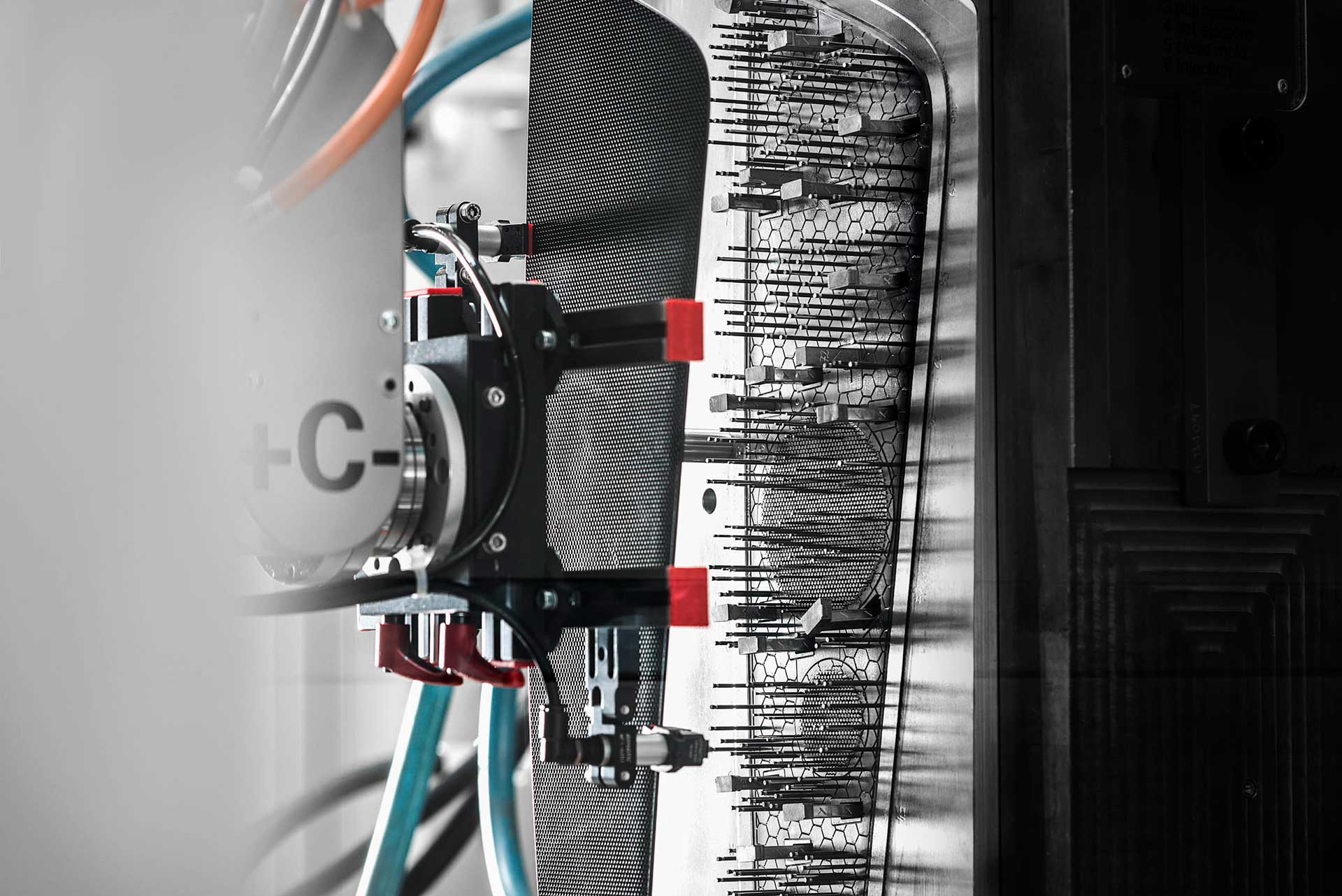

FILL ANALYSIS

As an additional service in our product development area, we create fill analyses for you. These simulations allow the optimization of injection points and gating systems for single-, multi– and family tools. In addition, predictions can be made for closing force, shot volume and cycle times. Problem areas such as poorly filling ribs, any air inclusions, binding seams in the visible area, etc. can be identified and avoided early on. This reduces the need for subsequent tool adjustments and thus saves time and money.

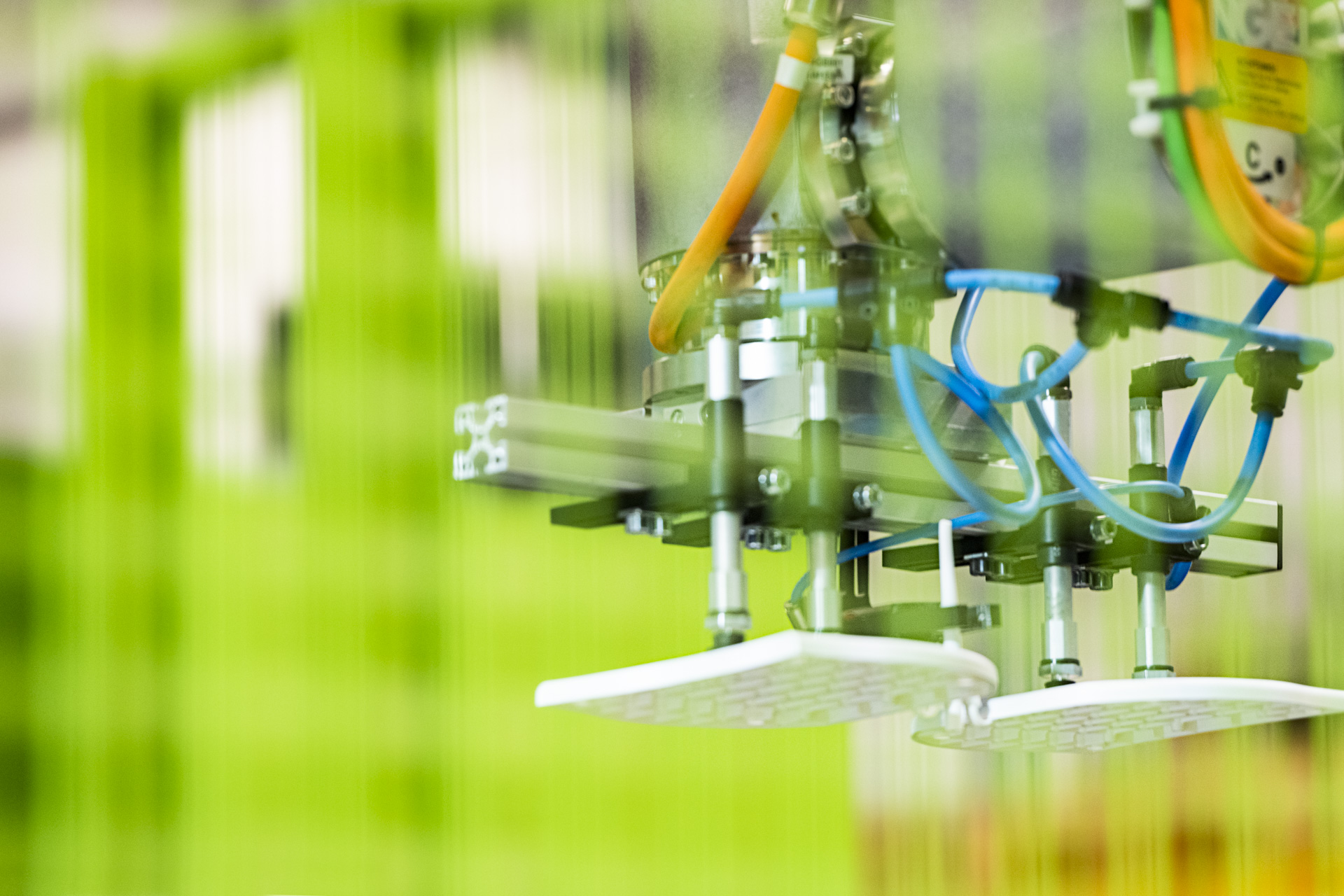

ASSEMBLY SERVICE

At our production facilities, complex subassemblies are assembled into finished products. The products can be delivered already packed for sale upon request.

ADDITIONAL SERVICES

In our production we offer a wide range of additional services. All products can be assembled and finished in our factory and can be delivered already packed for sale upon request.

• Sampling of all kinds • 3D measurement including surface feedback • Pad printing • Ultrasonic welding • 3D printing • Hot stamping • Punching • Bending • Laser engraving • Color marking • Laser edges • Labeling • Ultrasonic cleaning • Laser punching • Soldering • Riveting • Adhesive fixing